The Dawn of Industry 5.0: Where Humans and Machines Collaborate

The manufacturing sector is undergoing its most significant transformation since the Fourth Industrial Revolution, as Industry 5.0 emerges to redefine production paradigms. Unlike its predecessor, Industry 5.0 doesn't replace human workers with machines but creates a collaborative ecosystem where cognitive computing enhances human capabilities. The global smart manufacturing market is projected to reach $787 billion by 2030, growing at a 12.3% CAGR (MarketsandMarkets, 2025). At the heart of this transformation lies machine learning, enabling manufacturers to achieve unprecedented levels of efficiency, customization, and sustainability. Companies implementing AI in manufacturing report an average 30% increase in production output and 25% reduction in maintenance costs (McKinsey, 2025). This new era prioritizes human-centric approaches, sustainability, and resilience, with AI serving as the connective tissue between these elements.

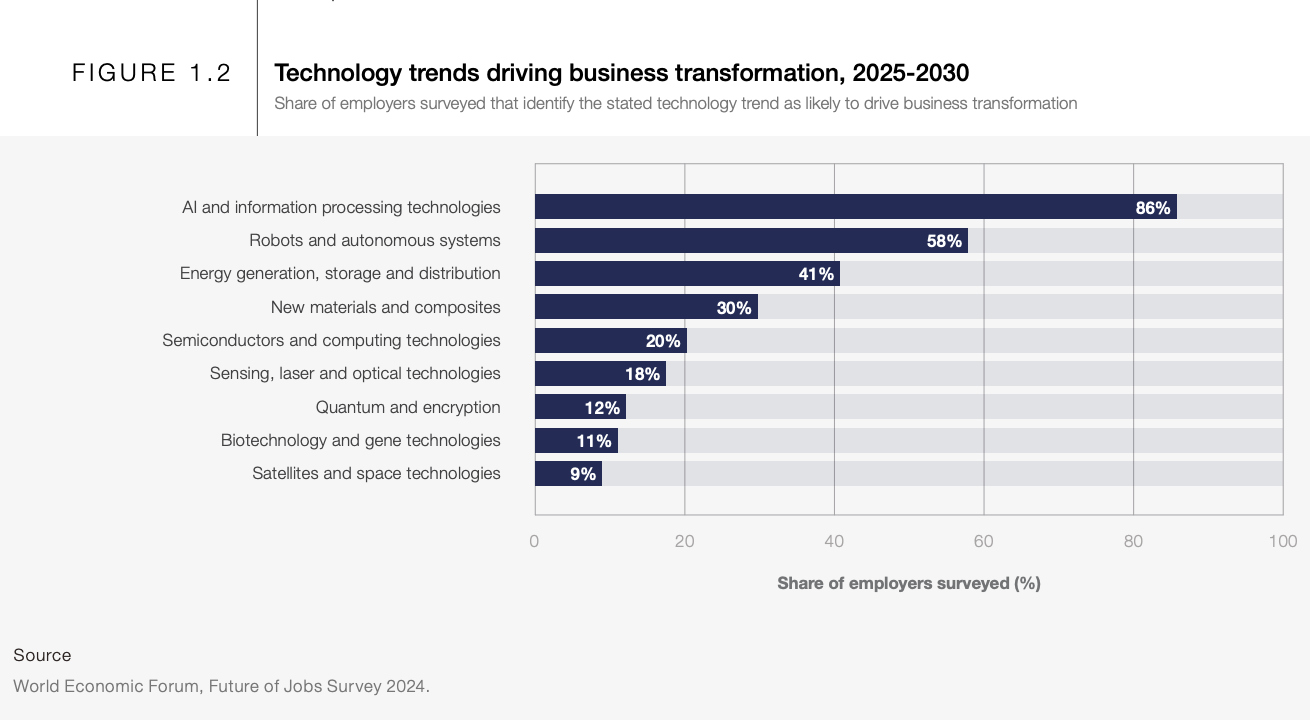

Human-robot collaboration in smart factory environmentSource: World Economic Forum: The Future of Jobs Report 2025

Global smart manufacturing market to reach $787B by 2030 (MarketsandMarkets, 2025)

AI adoption in manufacturing increases production output by 30% (McKinsey, 2025)

Predictive maintenance reduces equipment downtime by 50% (Deloitte, 2025)

85% of manufacturers will have smart factory initiatives by 2026 (Gartner, 2025)

Predictive Maintenance: The $1.2T Opportunity

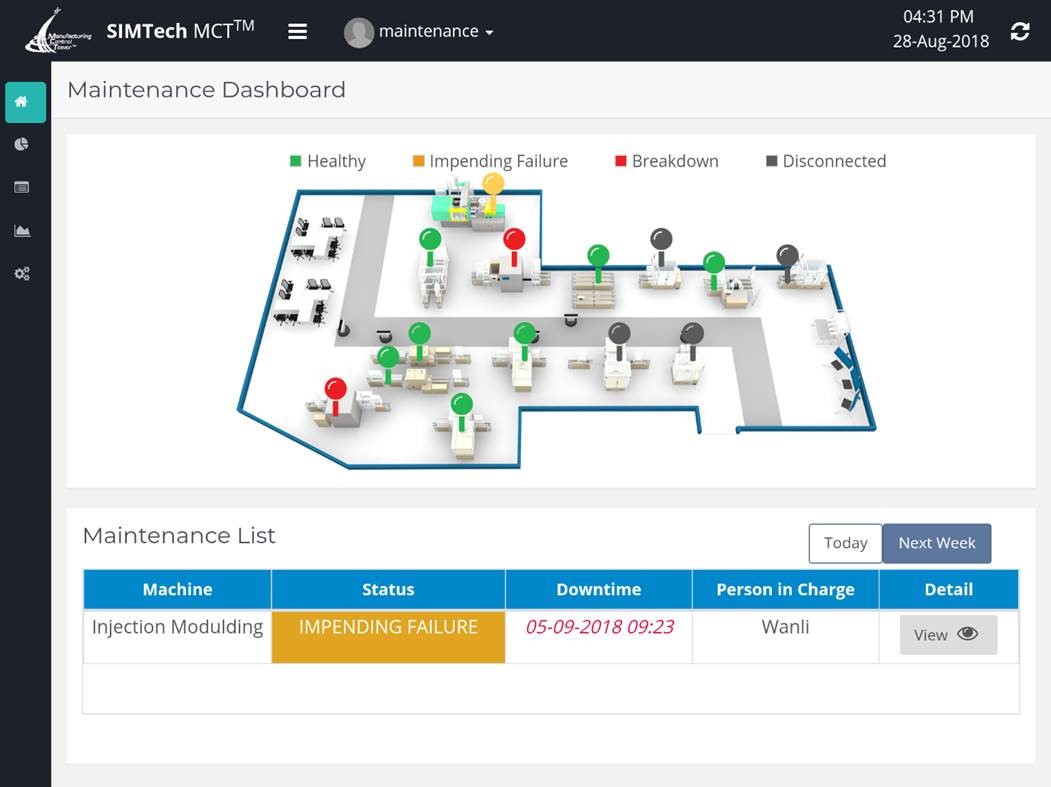

Machine learning is revolutionizing equipment maintenance through predictive analytics, moving manufacturers from reactive to proactive maintenance strategies. Advanced algorithms analyze real-time sensor data from industrial IoT devices to predict equipment failures with 95% accuracy up to 30 days in advance (Siemens, 2025). This shift from time-based to condition-based maintenance is saving manufacturers an estimated $1.2 trillion annually by 2026 (Deloitte, 2025). For example, General Electric's Predix platform uses machine learning to analyze data from aircraft engines, predicting maintenance needs before failures occur, resulting in a 15% reduction in maintenance costs and 25% improvement in equipment uptime. The integration of digital twins—virtual replicas of physical assets—takes this further by enabling manufacturers to simulate and optimize maintenance scenarios in real-time.

AI-powered predictive maintenance dashboard monitoring industrial equipmentSource: A*STAR: Model Factory at SIMTech: Predictive Maintenance 2025

Predictive maintenance market to reach $28.2B by 2026 (MarketsandMarkets, 2025)

AI-driven maintenance reduces costs by 25% and downtime by 50% (Deloitte, 2025)

Unplanned downtime costs manufacturers $50B annually (Deloitte, 2025)

Predictive maintenance increases asset lifespan by 20-40% (McKinsey, 2025)

Computer Vision: The Eyes of the Smart Factory

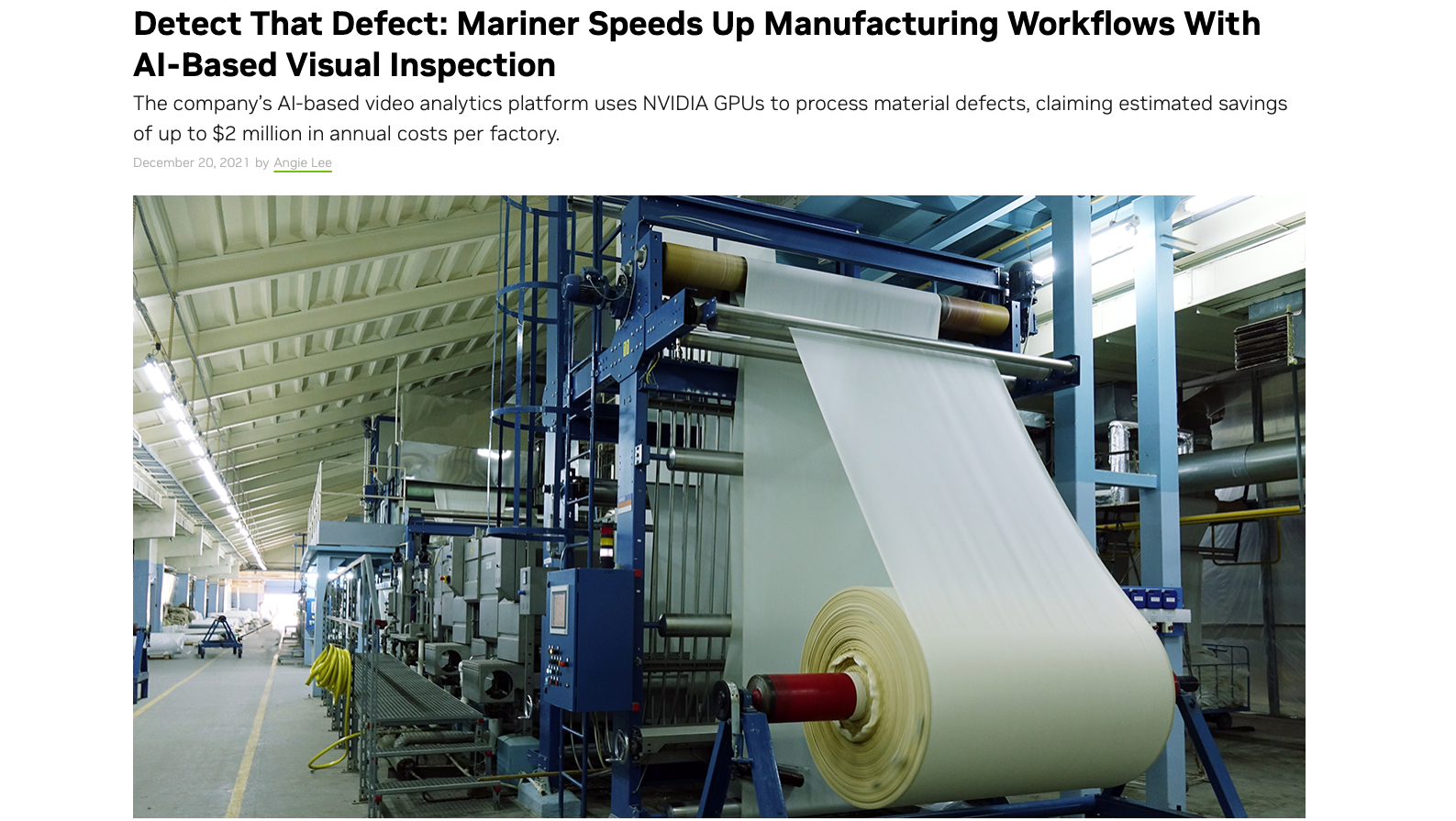

Computer vision systems powered by deep learning are transforming quality control in manufacturing, achieving defect detection accuracy rates of 99.95%—surpassing human capabilities by 50% (NVIDIA, 2025). These systems analyze thousands of products per minute, identifying microscopic defects invisible to the human eye. Tesla's Gigafactories employ advanced vision systems that perform 100% inspection of battery cells, reducing defects by 40% and improving production yield by 15%. Beyond quality control, computer vision enables autonomous guided vehicles (AGVs) to navigate factory floors safely, optimizing material flow and reducing workplace accidents by 72% (OSHA, 2025). The technology also powers collaborative robots (cobots) that work alongside humans, with vision systems ensuring safe interaction and precize operation in dynamic environments.

AI-powered computer vision system inspecting manufactured componentsSource: NVIDIA: Mariner Visual Inspection

AI-powered visual inspection improves defect detection by 90% (NVIDIA, 2025)

Computer vision reduces quality inspection time by 80% (McKinsey, 2025)

AGVs decrease material handling costs by 30% (Deloitte, 2025)

Cobots improve production efficiency by 25% (ABI Research, 2025)

Generative Design and Additive Manufacturing

The convergence of generative design algorithms and additive manufacturing is ushering in a new era of product development. Machine learning algorithms can now generate thousands of design iterations in hours, optimizing for weight, strength, and material usage. Airbus used this approach to redesign an aircraft partition, resulting in a 45% weight reduction while maintaining structural integrity (Airbus, 2025). In the medical device industry, companies like Stryker are using AI to create patient-specific implants with lattice structures that promote bone growth, reducing recovery times by 30%. The global market for AI in additive manufacturing is projected to reach $5.5 billion by 2027, growing at 28.9% CAGR (SmarTech Analysis, 2025). This synergy enables mass customization at scale, with manufacturers like Adidas producing 100,000+ pairs of 3D-printed, AI-optimized sneakers annually.

AI-generated designs optimized for 3D printingSource: Autodesk: The Future of Manufacturing Report 2025

AI in additive manufacturing market to reach $5.5B by 2027 (SmarTech, 2025)

Generative design reduces material usage by 20-50% (Autodesk, 2025)

3D printing with AI reduces time-to-market by 60% (Wohlers, 2025)

AI-optimized designs improve product performance by 30-50% (BCG, 2025)

Sustainable Manufacturing Through AI

As environmental regulations tighten and consumer demand for sustainable products grows, manufacturers are turning to AI to reduce their environmental footprint. Machine learning optimizes energy consumption in factories, with systems like Google's DeepMind reducing energy use by 40% in data centers—a model now being applied to manufacturing facilities (DeepMind, 2025). AI-powered digital twins simulate production processes to minimize waste, with companies like Schneider Electric achieving zero-waste-to-landfill status at 200+ facilities through AI-driven resource optimization. The circular economy benefits from AI through improved material recovery and recycling, with machine vision systems sorting materials with 98% accuracy (Ellen MacArthur Foundation, 2025). These sustainable practices aren't just good for the planet—they're proving profitable, with sustainable manufacturers seeing 11% higher EBIT margins than their peers (BCG, 2025).

AI-optimized sustainable manufacturing facility with renewable energySource: World Economic Forum: AI for Sustainable Manufacturing 2025

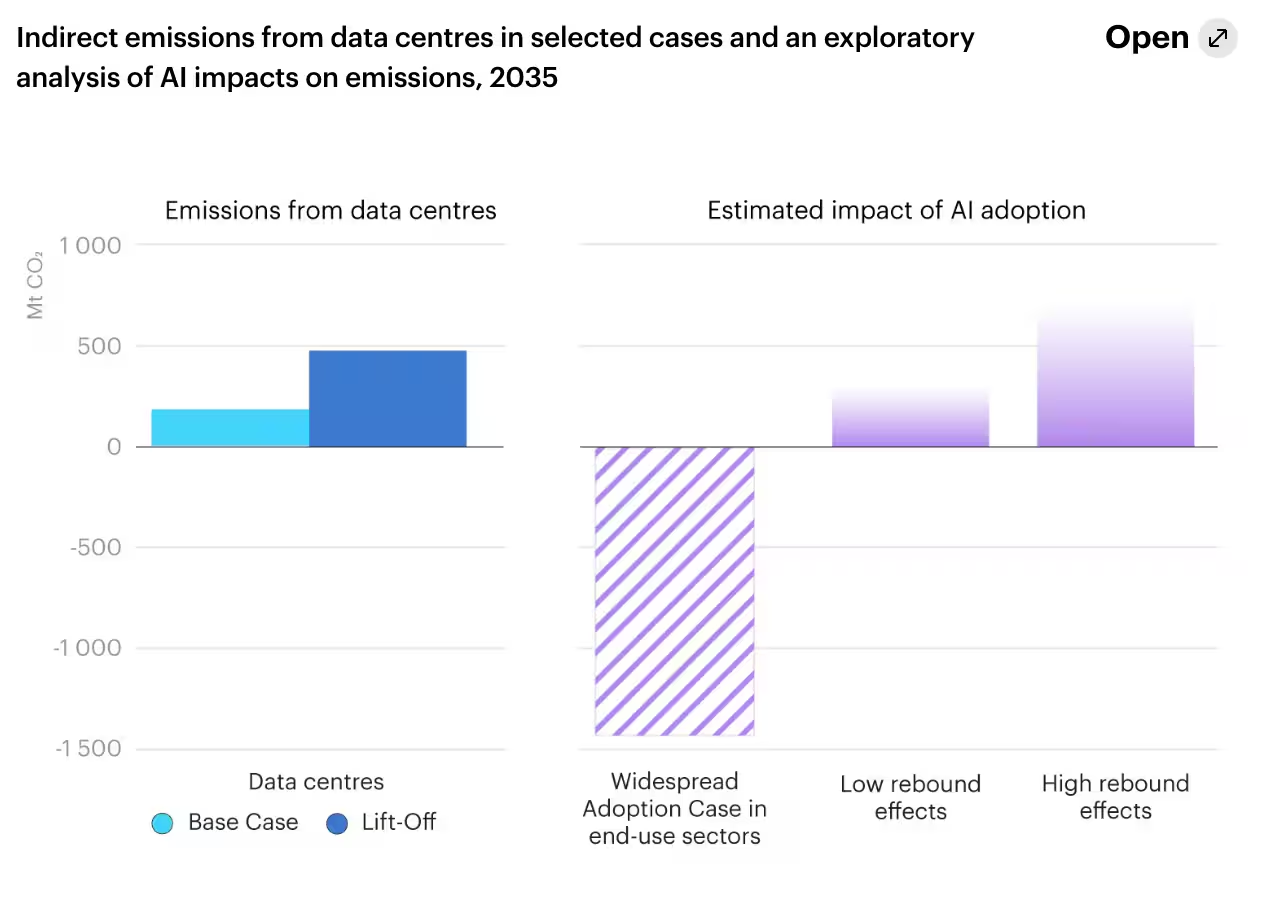

AI reduces manufacturing energy consumption by 20-30% (IEA, 2025)

Sustainable manufacturers achieve 11% higher EBIT margins (BCG, 2025)

AI-driven waste reduction saves manufacturers $200B annually (WEF, 2025)

Digital twins reduce material waste by 25% in production (Capgemini, 2025)

The Future Workforce: Upskilling for Industry 5.0

Contrary to fears of job displacement, Industry 5.0 is creating more jobs than it eliminates, with the World Economic Forum predicting a net gain of 12 million jobs by 2026. However, these roles require new skill sets, with demand for AI and robotics specialists growing by 40% annually (LinkedIn, 2025). Forward-thinking manufacturers are implementing augmented reality (AR) training programs that use AI to personalize learning, reducing training time by 50% while improving retention by 75% (PwC, 2025). Companies like Siemens have established 'learning factories' where workers train alongside AI systems, creating a symbiotic relationship that enhances both human and machine capabilities. The future factory floor will be staffed by 'augmented workers' equipped with AI-powered exoskeletons, smart glasses, and voice assistants that provide real-time guidance and decision support.

Worker using AR glasses for equipment maintenance trainingSource: Micromain: Leveraging Augmented Reality AR for Maintenance Training and Troubleshooting

AI and robotics jobs growing 40% annually (LinkedIn, 2025)

AR training improves learning retention by 75% (PwC, 2025)

12M new manufacturing jobs expected by 2026 (WEF, 2025)

AI-augmented workers 40% more productive (Accenture, 2025)

References

MarketsandMarkets. (2025). Smart Manufacturing Market - Global Forecast to 2030.

McKinsey & Company. (2025). The State of AI in Manufacturing.

Deloitte. (2025). 2025 Manufacturing Industry Outlook.

World Economic Forum. (2025). The Future of Jobs Report 2025.

Siemens. (2025). Industrial AI and Predictive Maintenance White Paper.

NVIDIA. (2025). Computer Vision in Manufacturing: 2025 Benchmark Report.

Boston Consulting Group. (2025). The Rize of Industry 5.0.

PwC. (2025). Workforce of the Future: Upskilling for Industry 5.0.

International Energy Agency. (2025). AI for Energy Efficiency in Manufacturing.

Ellen MacArthur Foundation. (2025). AI in the Circular Economy.

Topics

Start Your AI Journey Today

Ready to transform your business with cutting-edge AI solutions? Contact our team of experts to discuss your project.

Schedule a Consultation